Outic provides Zhejiang Weierbo Environmental Protection Co., Ltd., the largest automatic reagent system integrator in China, with high-performance electric differential pump products, and provides its customers with accurate addition of flotation reagents. This project is a copper concentrator project of Zijin Mining with a processing capacity of 150000 tons/day, which uses high-performance E01+electric differential products, and has accurate, reliable and easy to control performance.

Configuration scheme

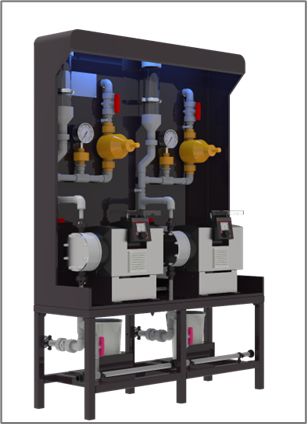

E01+M2 frame+50 E01+electric differential pumps

The addition of flotation reagents is a key link in the flotation process. The reliability and output accuracy of the reagent system directly affect the recovery rate and economic benefits of the entire concentrator. In the Wilbur non-ferrous metal beneficiation project, Otec has provided 50 E01+series heavy-duty electric differential pumps for the project. Its output features high precision output control in a large range. The transmission range is 10~8000ml/min, and the output reagent types are various flotation reagents, It includes xanthate, copper sulfate, sodium sulfite, etc. Because of the need for continuous and stable output without pulsation, the automatic reagent system of the whole flotation workshop is composed of E01+M2 frame, internal integrated damper, back pressure valve and various pipe valve assemblies, 25 frames and 50 E01+series electric differential pumps.

Configuration advantages

● Integrated damper and pipeline assembly, continuous output without pulsation

● Output interval 1:700, meeting the process conditions for adding various fluids

● Simple operation, more efficient use of equipment by operators

● High precision output, repetition error ± 0.3%

● Pipe network monitoring, real-time monitoring of pipe pressure to prevent blockage

● Diaphragm monitoring to prevent leakage caused by diaphragm rupture

● Equipped with remote communication interface to realize unmanned remote control and monitoring

Project results

This project provides precise process control for the concentrator, ensures more efficient flotation process operation, and provides more reliable technical support for Wilbur integrators.